The Early Days of Velcro

The concept of Velcro was inspired by nature. George de Mestral’s fascination with burrs led to the creation of the hook-and-loop fastener that we now know as Velcro. The first iteration of the product used cotton loops, but as technology progressed, manufacturers turned to synthetic fibers like nylon, which offered greater durability and resilience.

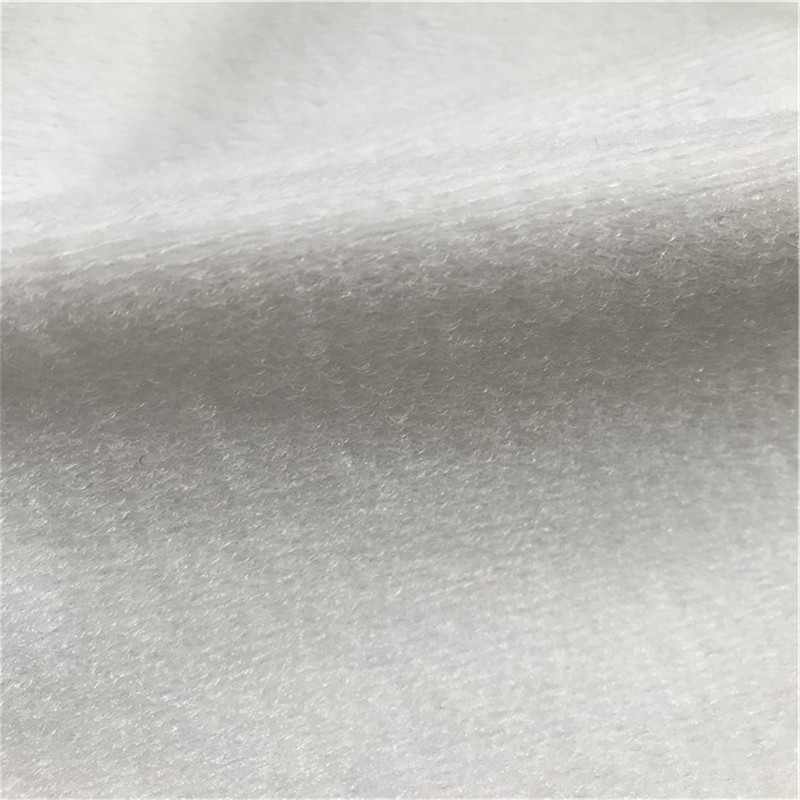

The loop side, made of nylon, quickly became the preferred material due to its ability to maintain its shape and strength after repeated use. Nylon also offered superior resistance to wear and tear compared to natural fibers, which made it ideal for high-demand environments.

Technological Advancements in Nylon Loop Velcro Fabric

In recent decades, advancements in textile manufacturing have led to the development of stronger, more efficient nylon loop Velcro fabrics. These innovations have resulted in several key improvements:

Stronger Fiber Composition: Modern nylon fibers are engineered to be even more durable, with improved abrasion resistance, making the fabric last longer and perform better under extreme conditions.

Improved Adhesion and Bonding: Advances in adhesive technology have improved the way the loop fabric bonds with the hook side, making Velcro fasteners more secure and resistant to separation, even under stress.

Customization: Manufacturers can now produce nylon loop Velcro fabric in a variety of thicknesses, textures, and colors. This customization allows for more precise application across different industries, from military gear to high-end fashion.

Sustainability Efforts: With growing environmental awareness, textile manufacturers are working toward creating more sustainable versions of nylon loop Velcro fabric. This includes using recycled materials and developing more eco-friendly production methods.

Impact on Modern Manufacturing

The versatility of nylon loop Velcro fabric has made it a go-to material in modern manufacturing. Here’s how it has influenced different sectors:

Automotive Industry: In the automotive sector, nylon loop Velcro is used to secure interior panels, trim, and carpets. Its durability and ease of use make it ideal for cars that undergo frequent wear and tear.

Medical Equipment: The healthcare industry benefits from Velcro’s ability to offer adjustable, secure, and hygienic fastening options. In medical devices like braces, straps, and surgical drapes, nylon loop Velcro fabric ensures both comfort and stability.

Aerospace and Defense: The military and aerospace sectors utilize nylon loop Velcro for everything from securing tactical gear to affixing items in aircraft. Its ability to withstand harsh conditions, including extreme temperatures and high stress, makes it indispensable.

Consumer Electronics: Nylon loop Velcro is often used in cable management systems, allowing consumers to organize and manage their electronic devices and accessories with ease.

English

English

Español

Español